Christmas is coming and my mind is on toys and gifts. Could I get them 3dprinted at home? If so, what are my options I ask the 3d print veteran Alice Taylor from Makie.Me, the creator of world’s first 3D printed toys.

Summary- by Eva Pascoe

Speakers:

Simon Gill – Executive Creative Director at LBi

Alice Taylor – MakieLab – Maker of the Makies, inventing the future of toys

Ann Marie Shillito – Anarkik3D.co.uk, Haptics and 3D Lab, Edinburgh

Martin Stevens – 3d Ltd

Chair: Ivan Pope – ThingMakers / Fabrivan, Brighton

Alice came to our Cybersalon meeting with tales of Makie dolls, her “fresh-off- the-printer” personalised creations composed of 3D printed faces, and funky, fabric clothes. Alice tells us that equipping the dolls with false eye-lashes from Boots has been one of the breakthroughs, as it gives them a whole new look. So, together a mix of 3D printing, a bit of traditional dress making and make-over tools all come together to create a very lovely toy.

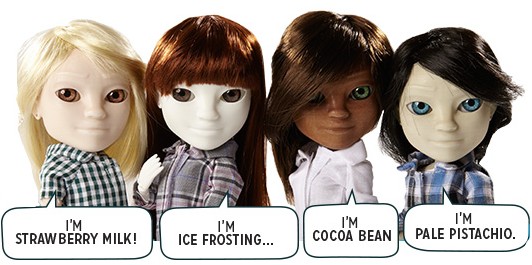

The story of the Makies started with an offer of all white, all porcelain dolls, that customers could get printed and add personalised fashion accessories. The users could design and play with the customised options live in the Makie.me studio. They could experiment in public, and Alice introduced a customised ‘hack’ version that could be played with before the dolls are even out of the prototype phase. This instant feedback and ability to improve your design immediately, on site, makes it a great experience. But it turns out it is the expanded option of choosing exactly your own skin colour that really proved to be the killer-app!

Alice came to our Cybersalon meeting with tales of Makie dolls, her “fresh-off- the-printer” personalised creations composed of 3D printed faces, and funky, fabric clothes. Alice tells us that equipping the dolls with false eye-lashes from Boots has been one of the breakthroughs, as it gives them a whole new look. So, together a mix of 3D printing, a bit of traditional dress making and make-over tools all come together to create a very lovely toy.

Meet the Makies

The story of the Makies started with an offer of all white, all porcelain dolls, that customers could get printed and add personalised fashion accessories. The users could design and play with the customised options live in the Makie.me studio. They could experiment in public, and Alice introduced a customised ‘hack’ version that could be played with before the dolls are even out of the prototype phase. This instant feedback and ability to improve your design immediately, on site, makes it a great experience. But it turns out it is the expanded option of choosing exactly your own skin colour that really proved to be the killer-app!

Alice is not just a creative force, but also a master of an express-startup school of Making. Her team managed to get from zero to Selfridges retail hero in just one year. Alice’s tip is to let the girls customise, play, create own dolls, like real ‘mini-me’, then the orders will flow as it becomes a very individual experience, in fact something of a therapy.

Makie.me is more of a platform than a product and that is why we are inspired by her success and the way she is open to share the designs with the world. Her designs are on Thingiverse.com, a website dedicated to the sharing of user-created digital design files. Alice notes that 3d printing is at about at the same level of maturity as the Web in 1998, a bit rough, non-commercial but technically already accomplished and ready to go mainstream, with design standards (STL files) already in place.

Ivan Pope, Fabrivan

Ivan Pope is the Brighton Maker, the brains behind Fabrivan Lab (fabrivan.com), with 3d printers, laser cutters, stencil tools and a variety of other aids under one (low) roof. His personal journey to 3D printing has started from the conviction that phase one has to be tool-sharing and design sharing and that that is what Fabrivan is all about. It is easily accessible, based near Brighton station and already benefiting design-wise from the oodles of customers floating in and out and testing the designs on-site (similar successful town-based makers grew already to significant micro-engineering companies

http://www.cybersalon.org/makingthings).

Minimising the obstacles for the new users means quick and easy access to a variety of tools, under the watchful eye of one of Fabrivan’s designers. Ivan uses Leapfrog printer (www.lpfrg.com) bought from IMakr.com, but comments that probably a better after-sales oriented supplier would be more appropriate for a newbie.

Printing A Gun

3D Gun

Ivan discussed the new option of 3d printing a gun. The first gun, printed in USA recently, called The Liberator was created by Defense Distributed (defdist.org) and was a 380 single shot pistol, with the STL design files released on the 5th May 2013 and fired by a student and activist Cody Wilson. By 9th May the US government was getting hot under the collar about it and ordered pulling the STL files from the publicly available servers. With a typical, UK punk twist on the story, our very own Victoria and Albert Museum acquired it for their London Design Week exhibition. Little did they know that it is impossible to obtain an export licence for a 3D printed gun, so eventually the V&A Museum showed their London entrepreneurial drive and curators’ grit and …printed the gun themselves!

The laws around the 3D printed technology are only just beginning to be formulated, so we can expect a fair amount of anarchy over the next few years, don’t say we didn’t warn you… We also discussed the fact that at the moment people like to scan existing objects, customise and instead of printing it themselves at home, sending off for printing, at least till the speed of the making improves.

At the moment, to print a toy solder of 5 cm height, takes about 1h20min, so it is not exactly a spectator sport! The market for print-ready designs is growing, as it may be the first step in the democratisation of the technology. Now we can choose, personalise and make, rather than create from scratch – still a rather frightening feat of creativity for those who don’t come from 3d design background and the closest they got to 3d objects creation is baking gingerbread men!

Simon Gill, Digitas Lbi

Simon Gill, Exec Creative Director from LBi dives right into the thick of the debate as he has originally trained as an industrial designer, so unusually for a typically 2D-Shoreditch hipster. For Simon, 3d and the world of atoms rather than bytes is something of a homecoming.

His slide showing a 360 degrees camera rig for a Sony campaign (http://www.andyhekimian.com/Sony-360-HD-Smartphone-Rig), created on a 3d printer for the mountain bicycle camera was a clear winner with the audience. The project demonstrates that the endless gadgets dreamt up by the extreme sport fanatics are finally moving out of ‘design fictions’ (as Bruce Sterling observed recently we have moved from science-fictions to design fictions (http://www.slate.com/blogs/future_tense/2012/03/02/bruce_sterling_on_design_fictions_.html), and into practical, albeit fairly out-there applications. As you can see on the photos, LBi boys had a ball with piecing it all together and testing on a wild ride in Arizona – the rig survived!

Our favourite was the MobilePhone-cum-Arduino-cum-coffee machine combo, using a clever switch and a screen (similar here http://www.youtube.com/watch?v=kpFqRwrbtLQ). It is clearly showing that digital innovation is still propelled by coffee (taking us back to the Trojan Coffee Machine with a Web Cam from 1991, an early example of how to use your tech to check if your coffee is ready without walking down the corridor to the kitchen. (http://knowyourmeme.com/memes/trojan-room-coffee-pot/videos). For the coffee enthusiasts, 3D printing is offering new ways to experience their favourite brew, not just printing new cups, but also improving the actual machines. (http://www.shapeways.com/blog/archives/2093-3d-printing-a-way-to-better-coffee.html)

Simon’s advice on choice of 3D printers is to ask the question what size of the product is needed, as the options will be determined by the size of the output. He makes an observation that it is the act of printing that is fun, so recommends just getting on with it. It is the journey that matters, not the destination sort of take on the 3D printing, but they audience nods enthusiastically so Simon has clearly hit the nail on the head. Some people fell in love so deeply with 3D printers that they designed a printer that prints itself, called Reprap, humanity’s first self-reproducing manufacturing machine just to make sure they always have one on hand! (http://reprap.org/wiki/RepRap)

Anne Marie Shillito, Anarkik 3D

Ann Marie Shillito is a jewellery artist, interested in making software artist-friendly. She is based in Edinburgh where her anarkik3d.co.uk company developed an intuitive 3d haptic mouse, with force feedback (http://www.anarkik3d.co.uk/haptics?___store=default). When you try to make a cup or a plate, you can feel on your fingers the actual stiffness or softness of the material, translated via a smart device with a haptic, tactile interface that has migrated from the world of games. Its easy, intuitive interface makes us all smile as it feels like pure magic- no more CAD dramas for newbies of the 3d printed world, and suddenly everybody feels more confident entering this new, somewhat intimidating universe of 3d objects.

Please get in touch with anarkik3d.co.uk for demo and courses as they are the only people in UK who work on the haptic interfaces for 3D printing.

Martin Stevens, 3D Ltd

Finally Martin Stevens from 3d Ltd gives a fascinating talk on the impact of 3d printing on kids in classroom settings. He is co-operating with Ann Marie Shillito in bringing the haptic 3d mouse into schools. He also invites all budding fashion and clothing designers to participate in TechnoPop, a new pop up event to be held in 1st March, 2014 in East London promoting creative possibilities of 3d Printed world. Box Park is hosting, please send proposals with your ideas to info@cybersalon.org.

We concluded with a lively discussion on the topics of copyrights, fair use of 3D design patents and challenge of home-made guns, examining the likelihood of this very authentic new technology allowing users to re-invent practically all their physical surroundings at a fraction of the price.

Thank you DigitasLBi for your hospitality, Simon, Kateryna and Julia for all their help and support, and to all for coming and making it such an amazing evening!